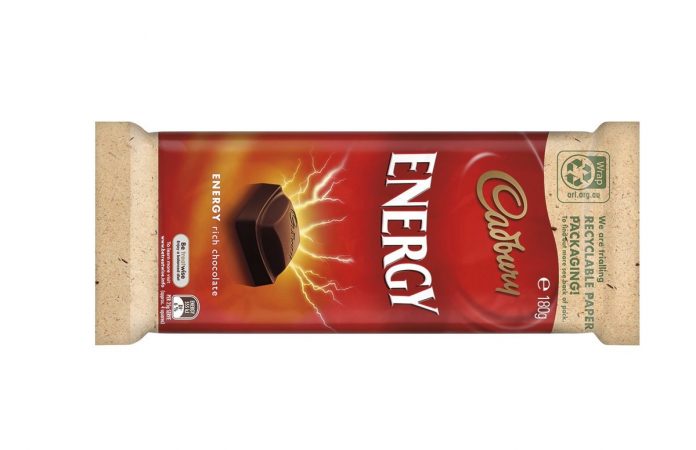

New paper packaging for Cadbury chocolate tablet

Consumer and manufacturer demand for more environmentally friendly packaging has never been stronger. Recently, Mondelēz International approached Syntegon Engineering science, formerly Bosch Packaging Technology, with a challenging request – to package Cadbury chocolate tablets in fully recyclable newspaper flow wraps. Following Syntegon Technology's vision to provide intelligent and sustainable solutions for everyone, work on sustainable solutions for paper flow wrapping had already taken shape within the company. A year of continued development resulted in a forming unit and sealing jaws for cold sealing applications. In the grade of an upgrade kit, the solution has now successfully been test trialed on Cadbury's flow wrapping machines for chocolate tablets – a format that poses a particular challenge.

Paper packaging for Cadbury chocolate tablet with Syntegon Engineering science

Founded in Birmingham, England, in the 1830s, Cadbury has been manufacturing cocoa products and chocolate for almost 200 years. While Cadbury's best-selling Dairy Milk choco late bar has won over chocolate lovers in every corner of the world, it offers a wide range of flavors, sizes, and products, including the Energy bar, which is sold in New Zealand.

Mondelez International, to which the Cadbury make belongs, has committed to making all of its packaging recyclable past 2025 through materials innovation, improved waste and recycling infrastructure, and consumer information and instruction. While plastic will continue to play an essential role in maintaining shelf life and minimizing food waste, some products could exist packaged in sustainable packaging materials, including paper catamenia-wrap.

The challenges of paper packaging

Newspaper packaging scores high because it tin exist reprocessed in existing paper recycling streams. Consumers perceive paper packaging every bit particularly sustainable and make their conclusion at the signal of sale based on touch and feel. Paper packaging receives increased attending with flow wraps, leading food manufacturers to consider the change from conventional packaging materials to paper-based packaging. However, paper is not as easy to package equally films and poses its own challenges when used on existing flow wrapping machines.

To come up with a suitable solution, Syntegon worked on an upgrade kit at its test laboratory in Beringen, Switzerland. "Equally a provider of packaging technology solutions, Syntegon is working at total blast to optimize its machine technology. We are striving to provide concrete technical solutions today for tomorrow's packaging engineering science," Christoph Langohr, project manager for sustainability, Horizontal Packaging, at Syntegon Technology explains. "Naturally, when Mondelēz International approached the states and asked to support their launch of a paper packaging solution for Cadbury's Energy chocolate tablet, we were excited to come up up with a solution."

Handling paper with intendance – choosing the correct packaging cloth

There is a wide range of paper suppliers who offer a variety of papers with dissimilar characteristics in stiffness and machinability. Paper packaging has several limitations, which makes it challenging to protect the product to the same degree as proven conventional films while generating the same output on the machine. Firstly, newspaper is a expert insulator. Secondly,paper is a reasonably stiff fabric, making it easy to crease or tear during the pack forming-process and damage it.

Still, Mondelēz International chose paper packaging and approached Syntegon. The shape of the chocolate tablet itself posed an additional challenge. Based on the specific requirements, Syntegon developed the forming unit "paper-ON-class" for their menses wrapping machines. "Formats like confined are easier to handle. In contrast, chocolate tablets similar Cadbury'due south Energy tablet are much broader and very apartment, which makes them more challenging to process. The new forming unit for Cadbury needed to take this into account," Langohr says.

Holistic arroyo – Upgrade-Kit "paper-ON-class"

The challenge is to develop newspaper-packaging solutions for machines already installed rather than new machines since many different formats must exist handled. To take a holistic approach, an upgrade kit was needed that suited all Bosch Packaging, at present Syntegon, flow-wrapping car types that apply cold-sealing technology, without compromising on output rates. Treatment paper on a menstruation-wrapping machine faces two major challenges. First, to handle the paper without breaking the grease and water-vapor barrier, and second, not to damage the flow wrap during sealing. This demands new sealing jaws that are customized for the specific paper material. Only then, reliable seals tin be generated.

The real deal – Installation of upgrade kit "newspaper-ON-grade"

To reach the best sealing results, Syntegon customized the new sealing jaws based on Cadbury's selected paper flick. Experts developed a new individual forming unit and sealing jaws for Cadbury, based on the desired pack size and the fabric characteristics, using 3D printed components. Later on putting the prototypes through their paces at the on-site test lab, it was time to manufacture the components. Syntegon Applied science installed the forming unit and sealing jaws on Cadbury'southward H-series flow wrapping machine.

After several trial-runs at their own facility, experts from Syntegon visited the Cadbury site to upgrade the existing menses wrapping machines and supervise the production run.

"We're committed to making all of our packaging recyclable by 2025, and nosotros're working hard to employ the right amount of packaging and simplify materials so they can be recycled. While we are making adept progress in reaching our 2025 ambition, partnerships assistance united states of america to create new materials, ameliorate infrastructure, and change consumer behavior," Maggie McKerr, senior sustainability managing director of Mondelēz Global External Communication team, states

Revolutionizing paper packaging

The new upgrade kit "paper-ON-class" for catamenia wrapping machines, which comprises a forming unit and sealing jaws for common cold sealing applications, is at the centre of the new newspaper packaging solution. Comprehensive tests have repeatedly demonstrated outputs without speed limitations. It proves that paper flow wrapping matches the performance of flow wrapping using films. The forming unit and sealing jaws can be used with dissimilar types of newspaper, regardless of thickness and supplier. As a upshot, newspaper packaging is now a real, sustainable option.

Source: https://packagingsouthasia.com/supply-chain-function/design-marketing/new-paper-packaging-for-cadbury-chocolate-tablet-51732/

0 Response to "New paper packaging for Cadbury chocolate tablet"

Post a Comment